Case Studies

Mold

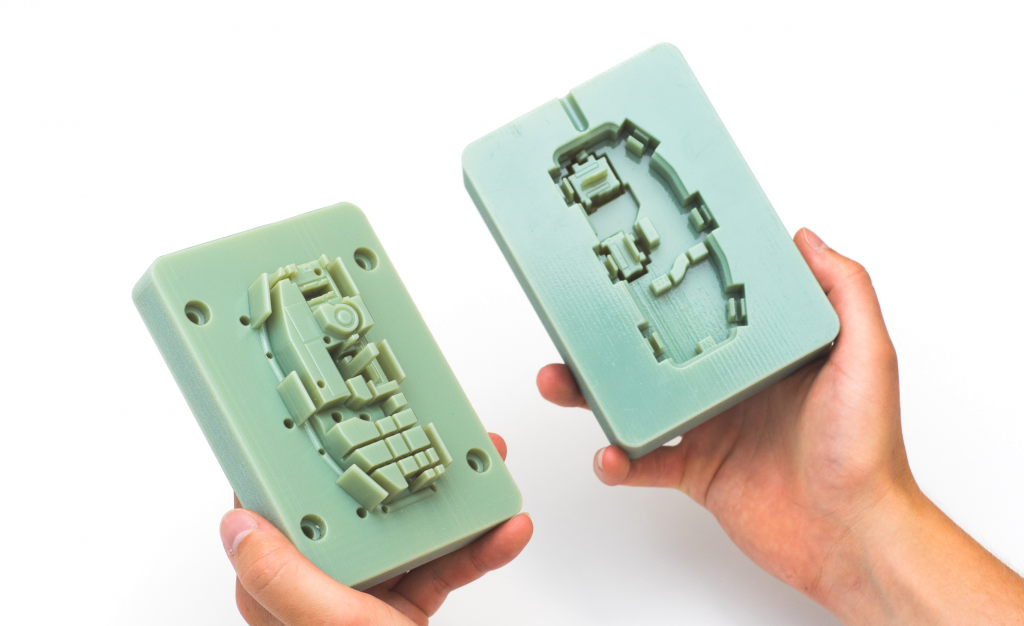

Print molds for prototyping

3D printers allowing mold designers to print production molds in one or two days as opposed to days and weeks for metal tools.

Why 3D Printing for the Mold Industry?

-

Shorten production time for mold creation

Mold designers are able to create molds quickly from 3D CAD files with a greatly reduced initial cost.

-

Design changes are more cost effective

In cases where design changes are required, a new iteration of a mold can be created in-house at minimal cost. This, combined with the speed of 3D printing, allows mold designers and engineers greater design freedom.

-

Accurate mold design

Molds created in Digital ABS material can be precisely built in 30 micron layers, with accuracy as high as 0.1 mm. These production features create a smooth surface finish so post-processing is not needed in most cases.

3

3 thoughts on “Mold”

Comments are closed.

Hello, I enjoy reading all of your article. I wanted to write a

little comment to support you.

My web-site :: 바둑이사이트

I appreciate, cause I discovered exactly what I was

taking a look for. You’ve ended my four day long hunt!

God Bless you man. Have a great day. Bye

Feel free to surf to my page; 먹튀검증 – ¸ÔƢ°ËÁő –

2surprised